Gimme Shelter: Advancing Affordable Housing

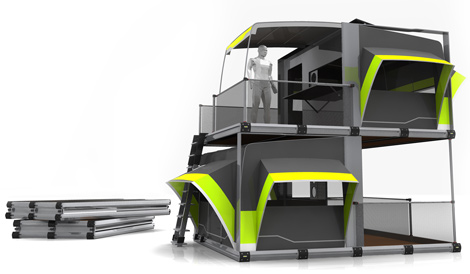

Rafael Smith explains his concept for the Uber Shelter (Purdue University)

There are currently over 36 million displaced persons all over the world. In the wake of recent natural disasters, it is more crucial than ever that adequate shelter be made available to help ease temporary and long-term homelessness.

Fortunately, over the past few years, several engineers have been working to make both low-income housing and temporary shelters more efficient and affordable.

Shelter Uber Alles

Computer rendering of the Uber Shelter (Purdue)

While on vacation in the Philippines three years ago, industrial engineering student Rafael Smith was stunned by the living conditions of poor residents. So for his senior design project at Purdue University, Smith devised a temporary shelter that’s portable, lightweight, easy to erect, and relatively comfortable.

Made from recyclable aluminum, his Uber Shelter prototype unfolds from a small, slab-like pack into a two-story unit the size of a small truck. Because it can house two families — one on each floor — it can accommodate more people on less land. It produces solar-powered electricity to run the lights, a small stove that can double as a heater, and a small refrigerator that can serve as an air conditioner.

Thanks to overwhelming interest from aid organizations, Smith and his team hope to have Uber Shelters ready to ship to Haiti within the next year. Here’s a video that shows their progress (as of March 2010):

Housing, Locally Grown

Loofahs — not just for showers anymore! Those scratchy scrubbing sponges come from a cucumber-like plant that’s indigenous to Paraguay. Now, a local industrial engineer, Pedro Padrós, has developed a way to mix loofahs and other vegetable matter with melted plastics to create a strong, lightweight, and recyclable building panel. The idea originated from social activist Elsa Zaldivar, pictured above.

Some years ago, Zaldivar successfully organized a rural women’s cooperative to grow and dry loofahs for sale overseas. But she wanted to find a way to put excess loofahs and waste to use in a building material. So she approached Padrós for help. After much trial and error, he developed a workable formula and a machine that mixes the materials and produces the panels. The panels cost about $3 per square meter. The low price is crucial, since Zaldivar wanted a product that Paraguay’s poor could afford. Zaldivar’s efforts won her one of the 2008 Rolex Awards for Enterprise. With the $100,000 prize money, she plans to open a promotion center and build three loofah-paneled model houses.

Filed under: Architectural, Civil, e-News, Environmental, Industrial / Manufacturing, Materials, Mechanical

Tags: Architectural, Environmental, Giving Back, Industrial, Materials, Mechanical