Engineering Artificial Skin

Human skin is extraordinarily sensitive – our fingertips can perceive extremely small differences in pressure, texture, and temperature. Mimicking this ability artificially is a real technological challenge, but fortunately electrical engineers at Stanford and UC Berkeley seem to be up to the task.

At Stanford, a team led by chemical engineering professor Zhenan Bao has developed an artificial skin that is reportedly over 1,000 times more sensitive than its human counterpart. It consists of a thin rubber material placed between two parallel electrodes. When an object touches the skin and compresses the rubber, the surrounding electrodes register this pressure and convert it to electrical signals.

In the past, researchers have had difficulty getting the rubber to maintain its shape after pressure is applied, but Bao’s team found an elegant solution: molding the rubber into a grid of tiny pyramids, which makes the material more resilient. It is also possible to adjust the sensitivity of the material by altering the size and density of the pyramids.

Incredibly, the Stanford skin can sense pressure lighter than the weight of a butterfly. Watch as researchers describe how this new ultra-sensitive material works:

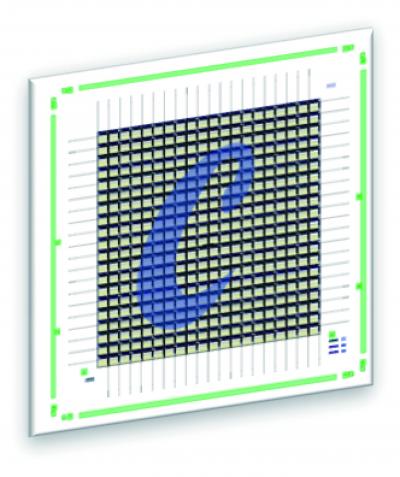

Meanwhile, across the Bay, UC Berkeley electrical engineers are taking a slightly different approach to artificial skin by using inorganic materials. The Berkeley group’s highly sensitive “e-skin” using germanium/silicon nanowires as transistors.

These researchers also made use of a pressure-sensitive rubber to detect outside contact, which they layered over a 18-by-19 pixel square matrix, with each pixel containing a transistor made up of hundreds of nanowires (see image at right). When pressure is applied, the transistors are able to sense the rubber compressing with high speed and precision.

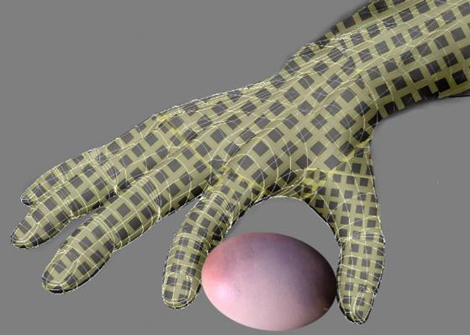

Like its organic cousin, this e-skin is extremely sensitive. If successfully integrated with a robotic arm, – a possible future challenge – it might allow an amputee to perform more complex motor tasks than ever before, such as holding delicate objects.

Beyond robotics and artificial limbs, however, these innovations have the potential to be used in variety of other applications, such as measuring the tightness of medical bandages and sensing whether sleepy or inattentive drivers have let go of the steering wheel.

Images:

L.A. Cicero/Stanford

Ali Javey and Kuniharu Takei/UC Berkeley

Filed under: Biomedical, Chemical, e-News, Electrical, Materials

Tags: Biomedical, Chemical, Electrical, Materials, Nanotechnology, Robotics